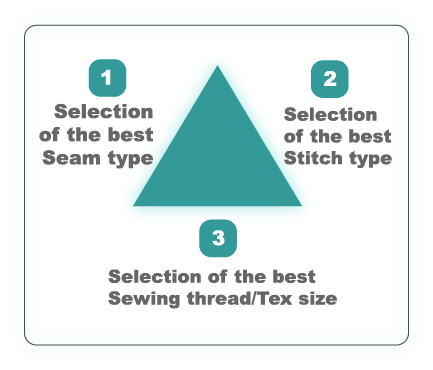

WHAT IS THE MANUFACTURING TRIANGLE?

While the fabric is the primary component needed to make garments, the expertise and skills of the manufacturer will determine the quality of assembly, the long-term durability, and safety performance of the protective clothing. The Manufacturing Triangle identifies 3 critical elements that the garment manufacturer needs to determine.

1. FABRIC PLACEMENT

How should fabrics be positioned so that the structural integrity at each junction of the garment can be maximized without waste or excessive use of fabric?

- Use Superimposed seam?

- Use a Lapped seam?

- Use a Safetystitch?

- Use an edge finish seam? (Flatlock)

2. STITCH SELECTION

What stitch type meets/exceeds the structural integrity needed for each junction of the garment to meet/exceed the performance requirements?

- 301 lockstitch – single row/double row

- 401 chainstitch – single row/double row

- Stitch density (stitches per inch [spi]) – 6-8 spi; 8-10 spi; 10-12 spi

- Strength efficiency of seam

- 100% catastrophic failure – replacement [no care and maintenance requirement]

- 80-85% seam efficiency – enables user to clean and repair as necessary during the service life of the garment

3. SELECTION OF SEWING THREAD

What sewing thread and tex size contributes the best value for factory efficiency, quality, seam efficiency, and economy?

Shirt Weight Knit Fabric [3.75 oz/yd2 to 4.25 oz/yd2]

CRAQ-SPUN® AR TYPE II |

||||

| SPUN TYPE 1 | COMPARABLE PERFORMANCE | HIGHER PERFORMANCE | HIGHER [PLUS] PERFORMANCE | |

| TEX SIZE | TEX 27 | TEX 18 | TEX 21/24 | TEX 35 |

| Break Strength | 1.5 lbs (6N) | 1.5 lbs (6N) | 2.25 lbs (10N) | 3.5 (15N) |

| Ydge/lb | 16,000 yds | 24,000 yds | 20,000 yds | 13,000 yds |

| Needle size | 10 | 8 | 10 | 12 |

Shirt Weight Woven Fabric [3.75 oz/yd2 to 4.25 oz/yd2]

CRAQ-SPUN® AR TYPE II |

||||

| SPUN TYPE 1 | COMPARABLE PERFORMANCE | HIGHER PERFORMANCE | HIGHER [PLUS] PERFORMANCE | |

| TEX SIZE | TEX 40 | TEX 21/24 | TEX 35 | TEX 45 |

| Break Strength | 2.0 lbs (6N) | 2.25 lbs (10N) | 3.5 lbs (15N) | 4.5 (15N) |

| Ydge/lb | 12,000 yds | 20,000 yds | 13,000 yds | 10,000 yds |

| Needle size | 12 | 10 | 12 | 14 |

Coverall/Trouser Woven Fabric [5.0 oz/yd2 to 6.5 oz/yd2]

CRAQ-SPUN® AR TYPE II |

||||

| SPUN TYPE 1 | COMPARABLE PERFORMANCE | HIGHER PERFORMANCE | HIGHER [PLUS] PERFORMANCE | |

| TEX SIZE | TEX 60 | TEX 35 | TEX 45 | TEX 60 |

| Break Strength | 3.0 lbs (13N) | 3.5 lbs (15N) | 4.5 lbs (20N) | 5.5 (24N) |

| Ydge/lb | 8,000 yds | 13,000 yds | 10,000 yds | 8,000 yds |

| Needle size | 16 | 12 | 14 | 16 |

CRAQ-SPUN® AR TYPE II |

||||

| SPUN TYPE 1 | COMPARABLE PERFORMANCE | HIGHER PERFORMANCE | HIGHER [PLUS] PERFORMANCE | |

| TEX SIZE | TEX 70/80 | TEX 45 | TEX 60 | TEX 70/80 |

| Break Strength | 4.5 lbs (20N) | 4.5 lbs (20N) | 5.5 lbs (24N) | 6.5 (29N) |

| Ydge/lb | 6,000 yds | 10,000 yds | 8,000 yds | 6,000 yds |

| Needle size | 18 | 14 | 16 | 18 |

Heavy Weight Woven Fabric [7.0 oz/yd2 to 9.0 oz/yd2]

CRAQ-SPUN® AR TYPE II |

||||

| SPUN TYPE 1 | COMPARABLE PERFORMANCE | HIGHER PERFORMANCE | HIGHER [PLUS] PERFORMANCE | |

| TEX SIZE | TEX 90-100 | TEX 60 | TEX 70-80 | TEX 90-100 |

| Break Strength | 5.5 lbs (24N) | 5.5 lbs (24N) | 6.5 lbs (29N) | 9 (40N) |

| Ydge/lb | 4,800 yds | 8,000 yds | 6,000 yds | 4,800 yds |

| Needle size | 20 | 16 | 18 | 20 |